Research areas

Research areas being pursued in the group include:

- Lightweight materials: to evaluate, design and develop various lightweight structural materials.

- Manufacturing: to understand multiscale and multiphysics phenomena in manufacturing processes and how manufacturing alters microstructural features in materials.

- Mechanical behaviour: to reveal underlying physical and structural mechanisms for mechanical behaviour of materials (e.g. deformation, fracture, fatigue and dynamic impact).

Below are some highlights of the research on the manufacturing, microstructure and mechanical behaviour of various materials, supported by the funding agencies.

- Additive manufacturing of metals and lattice structures >>

- Light alloys (Ti, Al) >>

- Metal foams >>

- Polymeric foams and fibre reinforced composites >>

- Ceramics >>

- Integrated material modelling to relate manufacturing to final performance >>

Additive manufacturing of metals and lattice structures

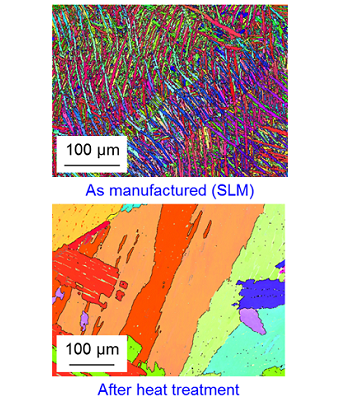

Ti-6Al-4V alloys manufactured by selective laser melting (SLM)

- Effect of SLM processing parameters and subsequent heat treatment on microstructure and texture.

- Simulation of the SLM process and the diffusion in heat treatment.

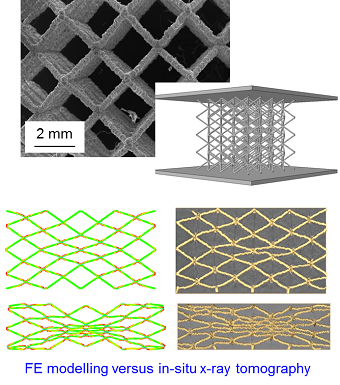

SLM stainless steel 316L lattice structures

- Constitutive equation of individual SLM struts in the lattice.

- FE modelling of deformation and failure behaviour for the design and optimisation of lattices.

Light alloys (Ti, Al)

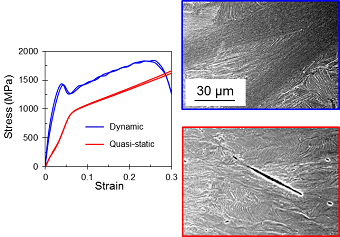

Micromechanism for the high rate behaviour of Ti-6Al-4V alloys

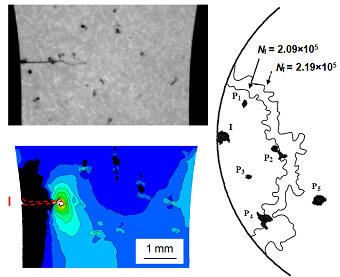

The 3D interaction between porosity and fatigue crack evolution in cast aluminium alloys

Metal foams

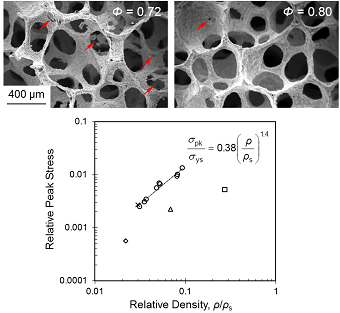

Open-cell Inconel foams

- The slurry coating technique developed to manufacture the open-cell foam.

- Effect of slurry composition (Φ) on microstructure and mechanical properties.

- Unit cell size effect on the sound absorption capability.

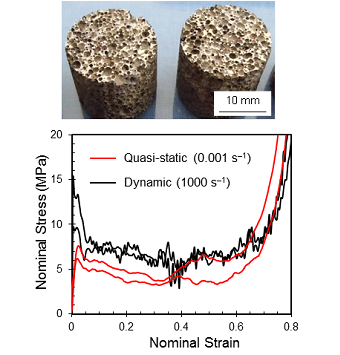

Closed-cell magnesium foams

- Unit cell homogeneity enhanced by the improved thermal stability during foaming.

- Strain rate dependent fracture mechanisms related to rate sensitivity of bulk properties.

Polymeric foams and fibre reinforced composites

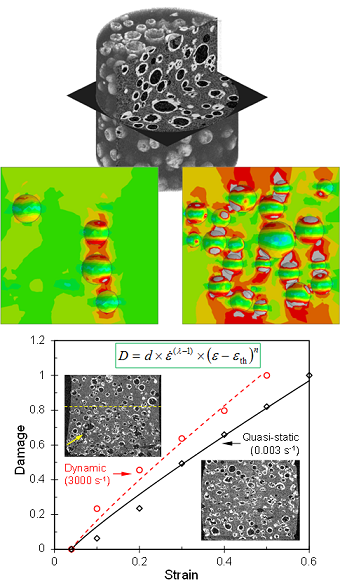

Syntactic foams

- The 3D real time failure process in cenosphere epoxy syntactic foams.

- FE modelling of the effect of cenosphere volume fraction for virtual design of the foam.

- Strain rate dependent failure mechanism in 3D.

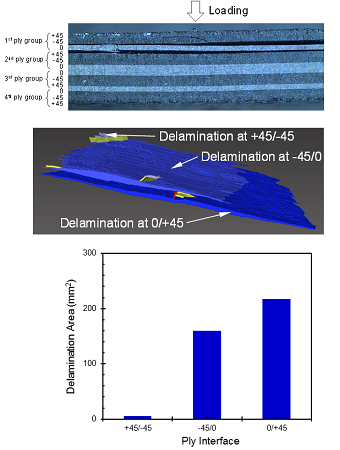

Carbon fibre reinforced polymeric (CFRP) laminates [+45/-45/0]2s

- Statistical analysis and prediction of flexural fatigue life.

- Characterisation and quantification of 3D fatigue damage by x-ray tomography.

Ceramics

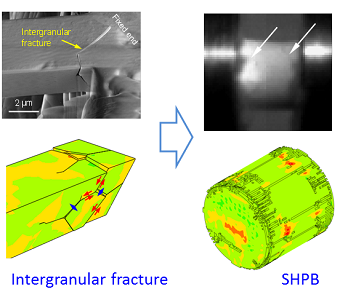

Multiscale failure phenomena in armour ceramics

- Voronoi cell finite element modelling of the intergranular fracture mechanism in polycrystalline alumina.

- SHPB tests and FE modelling of dynamic failure and fracture mechanism in alumina.

Integrated material modelling at various scales

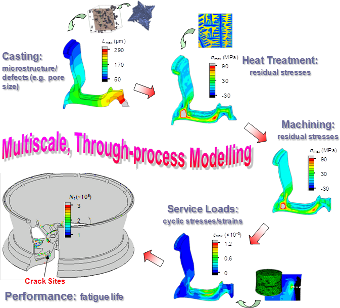

Multiscale, through-process modelling to predict the fatigue life of cast aluminium alloy components

- Simulating the microstructure, and residual stress in each processing stage.

- Prediction of the fatigue life of Al alloy wheel by linking each simulation.

Funding

Our research has received funding from:

University of Glasgow (2017)

NTU, MOE, MINDEF, A*STAR, DSO National Laboratories, ST Dynamics (2010 – 2017, all in Singapore)